Manufacturing Optimization: Search & Stop

Let's use the wall-clock factory model created in a previous exercise and deploy a "Search & Stop" optimization approach based on Monte Carlo sampling to identify the critical bottlenecks processes.

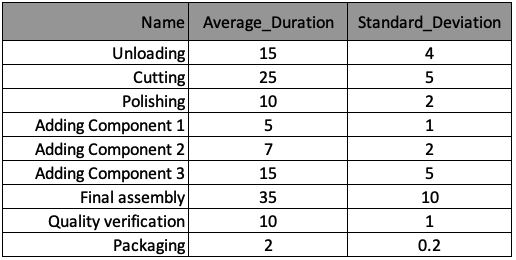

The manufacturing process is summarized in the table below, and the information has been stored in a list of dictionaries named processes, with one dictionary per process. The keys of this dictionary correspond to the table column headers.

The plot_results() method to generate the plots in this exercise has been pre-loaded and is shown below.

def plot_results():

df_disc = pd.DataFrame({cNam[0]: process_line_space, cNam[1]: time_record})

fig = sns.lineplot(data=df_disc, x=cNam[0], y=cNam[1], marker='o')

plt.grid()

fig.set(xlim=(0, len(processes)))

fig.set(ylim=(0, 180))

fig.set(xticks=process_line_space)

plt.plot()

The Monte-Carlo sampling loop will produce a series of possible process trajectories and stop when the desired condition has been met, as shown in the figure.

This exercise is part of the course

Discrete Event Simulation in Python

Exercise instructions

- Set a loop to run simulation trajectories while

run_iis equal to zero ortotal_duration[run_i]is higher than 85 hours (i.e., stop condition:total_duration[run_i]equal or less than 85 hours). - Run the Monte Carlo engine stored in the function

run_monte_carlo().

Hands-on interactive exercise

Have a go at this exercise by completing this sample code.

def run_monte_carlo():

run_i = 0

# While-loop with the stop condition

____

run_i += 1

env = simpy.Environment()

env.process(manufractoring_process(env))

env.run()

plot_results()

plt.show()

# Call the run_monte_carlo function

____